— 8 min read

The Ultimate Guide to Construction Management

Last Updated Apr 5, 2024

A successful construction project requires a series of complex tasks to be completed within the budget and time requested by an owner. Many different trades must be coordinated to perform tasks safely and at the right time — and to the quality expectations of an owner. Increasingly, project owners are turning to construction managers to supervise and manage project delivery.

The construction manager’s job is to ensure the project is completed on time, within the budget, and according to the contract requirements. However, because of the wide variety of activities involved in managing a construction project, the terms “construction management” and “construction manager” can mean different things. In this article, we’ll explore the main activities involved in construction management, and the varied roles a construction manager may play in delivering a project.

Table of contents

What is Construction Management?

Construction management is a specialized field of project management that involves supervision and coordination of construction activities to ensure successful project delivery. The term can also refer to a field of study: Many colleges and universities offer degree programs in construction management.

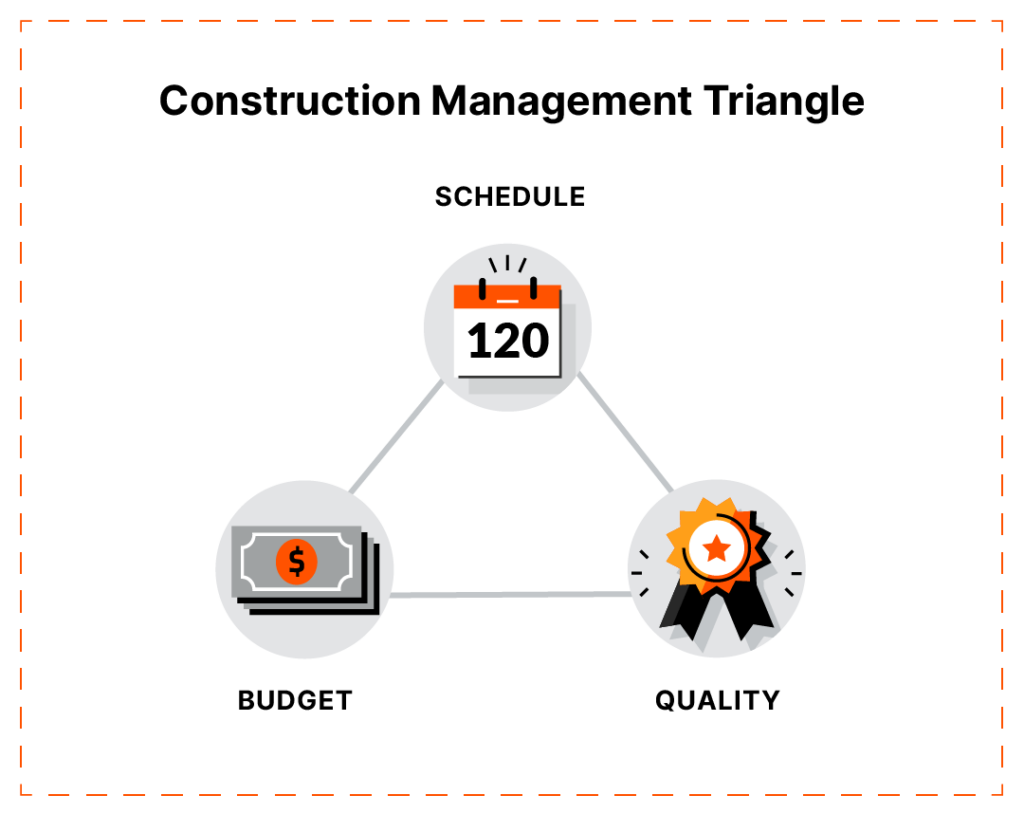

The ultimate goal of construction management is to minimize risk by controlling a project's schedule, budget (cost), and quality — also known as the "project management triangle."

This can be broken down into a variety of activities, which may include:

- Project planning

- Design coordination

- Cost management

- Quality management

- Contract administration

- Safety and compliance

- Risk management

- Documentation and reporting

- Project closeout

On complex projects, these duties may be divided between multiple project or construction managers, with each responsible for a different focus.

The Role of the Construction Manager

A Construction Manager (CM) is typically a person or company that provides construction management services to a project owner or property developer. They have extensive experience, training, and technical knowledge around construction methodologies, building codes, and drawings. A CM often acts as a representative for the project owner, bridging the communication gap between designers, engineers, and contractors to streamline project delivery.

A Construction Manager may be hired as an employee, or work as an independent contractor on a specific project. However, a CM can serve in a variety of different capacities. An owner may hire a construction management firm to act as their representative for the duration of a project, from conception to closeout. They may hire a general contractor as a CM to both consult during the design phase and perform actual construction work. A general contractor may even employ a construction manager as an employee to oversee construction of a large project or group of projects.

| A CM can be: | Hired by | Role | Example |

| A CM firm | Owner/Developer | Construction Manager as Agent or Owner’s Rep | A healthcare company hires a Construction Manager as Agent to provide consultative services during construction of a new hospital. |

| A General Contractor | Owner/Developer | Construction Manager at Risk (CMAR) | A commercial developer selects a GC to provide input during design; the agreement is amended to a GMP prime contract in preconstruction. |

| An employee | Owner/Developer | Construction Manager or Project Manager | A large retail chain employs a construction manager to oversee development of new stores. |

| An employee | General Contractor | Project Manager | A GC is launching a new public works division, and hires a CM to manage contracts and subcontractors. |

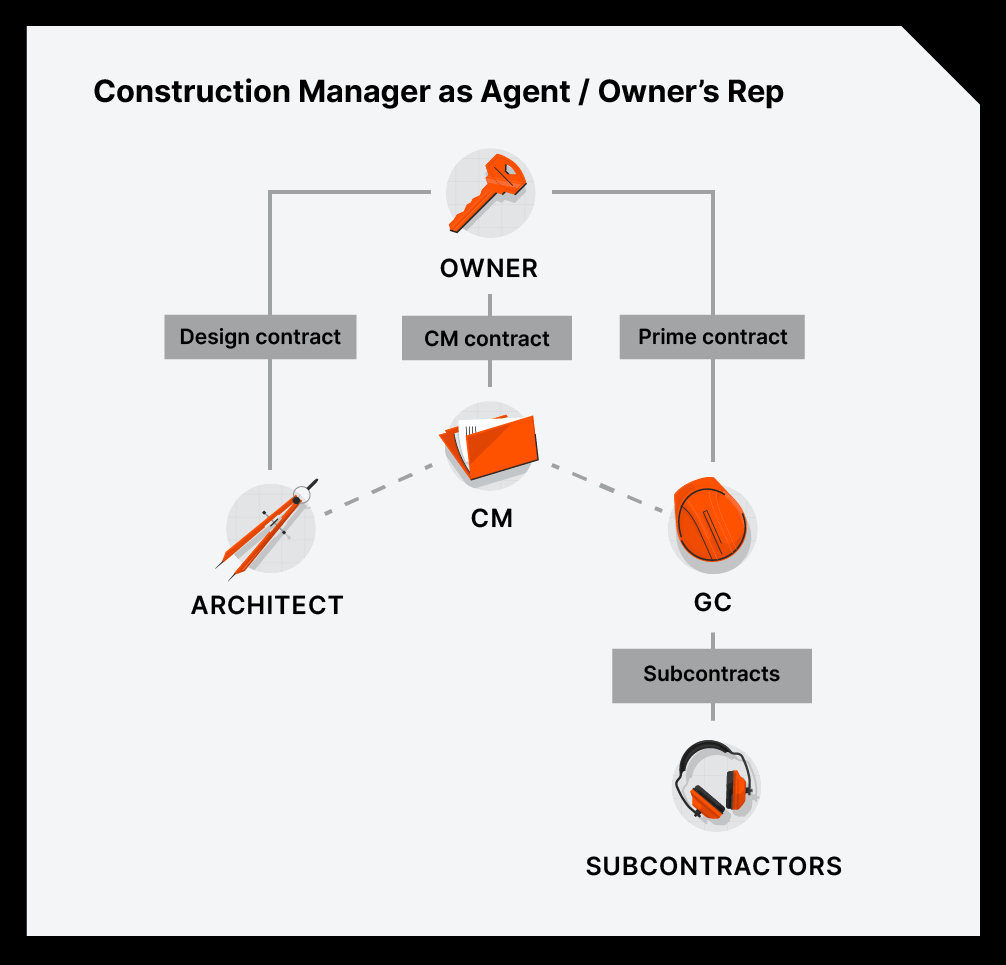

Construction Manager as Agent

A Construction Manager as Agent, often called an Owner’s Rep, acts as an advisor or consultant to the owner throughout the construction process, from early planning and design stages to the project's completion. In this role, they do not directly engage in construction activities or have contractual relationships with the subcontractors. Instead, they provide expertise to assist the owner in making decisions and coordinating the project.

Construction Manager at Risk (CMAR)

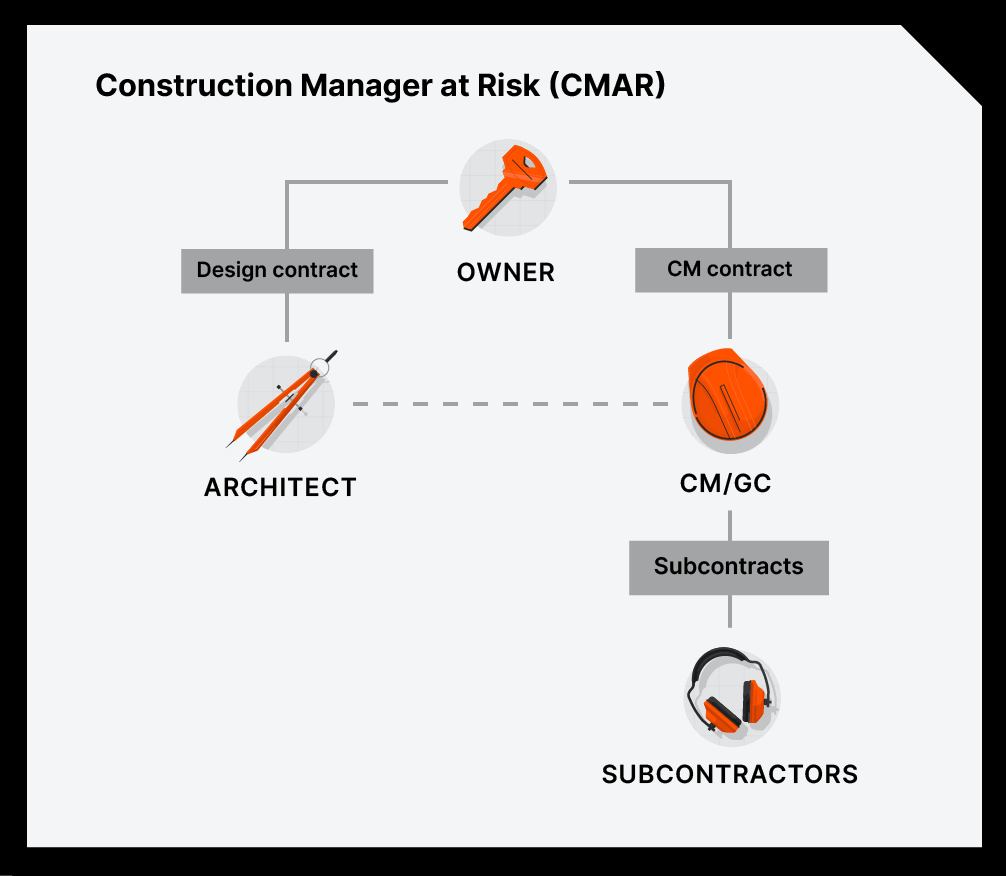

Construction Manager at Risk (CMAR) is a common project delivery method in which the owner selects a general contractor during predevelopment to consult on design. Throughout the design phase, the CM offers input to ensure that the building’s design is feasible and balanced against other interests, like budget and schedule. Their involvement prior to breaking ground enables the contractor to recommend alternative materials or methods that reduce owner costs through value engineering.

As both the CM and general contractor, they also solicit bids from subcontractors during the design phase. Prior to construction, they establish a guaranteed maximum price for the project.

This arrangement can be advantageous for all of the parties involved:

- Designers are able to work collaboratively with contractors from an early stage to ensure the feasibility of the construction drawings.

- Property owners establish a guaranteed price for the project, potentially limiting their risk during the construction phase.

- Contractors are able to provide input and solicit bids earlier in the project, possibly improving the schedule and budget along the way.

Using CMAR, an owner establishes a relationship with a construction manager who acts as a consultant and expert—and the CM has a financial incentive to act in the owner’s best interest.

Construction Manager vs Project Manager

The difference between a Construction Manager (CM) and Project Manager (PM) isn’t always clear. In fact, the terms are often used interchangeably in the building industry.

Construction Managers most commonly work for the owner to provide input on design feasibility and/or coordinate construction activities, managing the GC on the owner’s behalf. Project Managers are often hired by a contractor to oversee the administrative aspects of the building project, like scheduling and logistics.

In practice, however, the line between a CM and PM is often heavily blurred. The actual job title activities can vary greatly depending on the type of company they work for, or the specific role they are hired to fill. Regardless of the job title, most opportunities for both roles require candidates to have a background in construction management.

For example, owners and developers often hire a Construction Manager to supervise a single project or multiple projects. In this capacity, they are often involved in the selection of the general contractor, and they are responsible for protecting the owner’s interests.

General contractors, similarly, may hire a Project Manager to supervise multiple projects. But they may also assign multiple project managers to a large development, where each PM is responsible for a different phase or specific aspect of the build.

Job Outlook for Construction Managers

- Median Salary: $98,890 per year or $47.55 per hour (BLS, 2021)

- Number of Jobs: 478,500 (BLS, 2021)

- Job Growth: 8% (BLS, 2021-2031)

- Education: B.A. in Construction Management, Construction Science, or related field

On budget, on schedule, and in control.

Build with less risk and bigger profits.

The Study of Construction Management

Hundreds of colleges and universities worldwide offer both bachelor’s and master’s degree programs in construction management. While each school offers its own unique curriculum, CM degree programs often require students to complete similar coursework to develop a well-rounded understanding of the industry, building methods and materials.

General studies often include courses in:

- Physics

- Mathematics (Algebra, Trigonometry, Statistics)

- Data analytics

- Law

In addition, students must complete a variety of construction-specific courses, including:

- Safety and risk management

- Construction contracts

- Project cost and accounting

- Estimating

- Construction materials and methods

- Construction equipment and productivity

- Electrical systems

- Mechanical and plumbing systems

- Structural systems

- Engineering (environmental, civil)

- Land development

- Building information modeling

- Project management software

Some schools include even more specialized coursework for complex project types or focus areas. For example, the construction management program at Virginia Tech includes courses on Airport Planning and Design, Planning Transportation Facilities, and even Forensic Engineering.

Learn more: Career Paths to Management in Construction

The Future of Construction Management

As the construction industry continues to evolve and grow, so do the complexities of projects. Construction managers are becoming critical to the success of projects and keeping up with technology. Smart buildings, robotics and artificial intelligence are becoming the new normal. The field of construction management is already becoming more specialized, with firms offering services tailored to specific types of building projects, from healthcare to data centers to infrastructure projects. As the construction industry continues to evolve and grow, so do the complexities of projects.

Construction managers are becoming critical to the success of projects and keeping up with technology. Smart buildings, robotics and artificial intelligence are becoming the new normal. The field of construction management is already becoming more specialized, with firms offering services tailored to specific types of building projects, from healthcare to data centers to infrastructure projects.

Owners now request experienced construction managers to represent them — construction managers that provide more real-time visibility into project data and analytics that help improve efficiency on both current and future projects. Advancements in construction management software continue to transform the way owners and CMs coordinate, track and share data on every aspect of a project, from jobsite progress to financial performance.

Categories:

Tags:

Written by

Daphene Koch

Daphene is a construction consultant. She previously worked as a senior trainer at Procore. She has worked in a variety of roles on multi-million dollar construction projects, including project manager, field engineer on international EPC projects and owner's rep on industrial projects. Daphene was also an Associate Professor at Purdue University, where she helped to develop the construction management curriculum. She has a BS in Building Construction Technology, an MS in Construction Management, and a PhD in Educational Technology. She lives in Lafayette, Indiana.

View profileBryan Magargee

Bryan Magargee is a Strategic Product Consultant for Procore with a decade of experience in construction project management where he managed achitects, contractors and engineers. Bryan is focused on implementing technology to streamline processes, production and efficiency.

View profileWin More Work

Get discovered for relevant work on the Procore Construction Network.

Explore more helpful resources

Construction Teamwork: Build a Solid Foundation With the Right Team

Construction is an industry of collaboration — no one person completes any job on their own. It could easily be argued that the most important skill for anyone in this...

8 Tips for Managing Multiple Construction Projects

By its nature, construction work is a juggling act, with project managers and general contractors (GC) constantly adapting to changing conditions, planning to make sure there are enough materials and...

Prefab Construction: The Risks and Rewards of Prefabrication

Prefabricated or “prefab” construction is similar to assembling a set of Lego blocks: Components are manufactured or assembled at a separate location and then assembled on-site. Compared with the traditional...

Construction Site Logistics: Best Practices for Building Smarter

The effective management of construction site logistics can separate a timely, on-budget and high-quality construction project from one that falls short. Construction site logistics refer to the operations that need...