Ready to see it in action?

Stop jumping between apps to get a clear view of your project’s status.

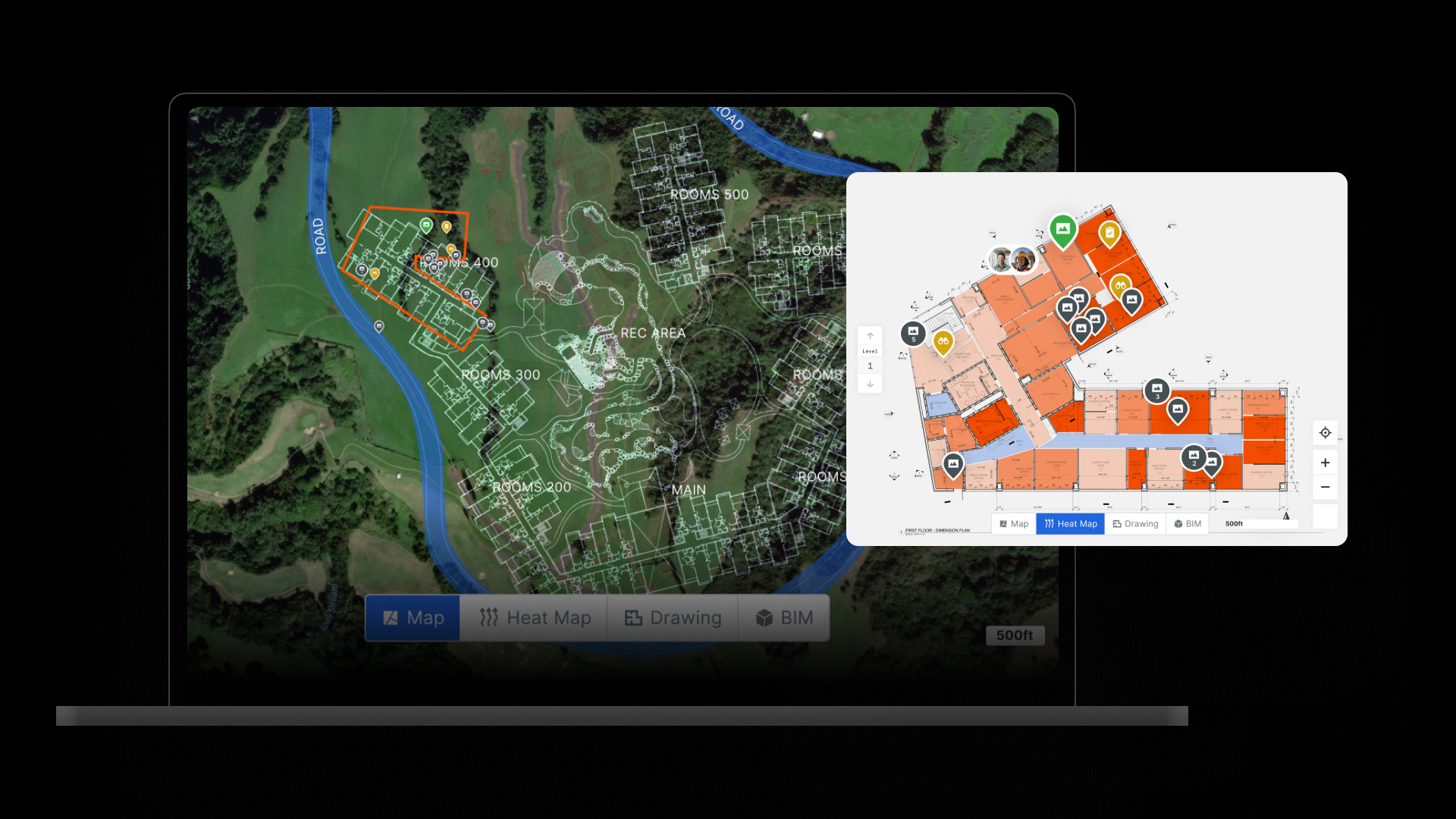

Construction Mapping Software

View photos on a dynamic map to quickly understand work status and minimize delays.

Procore Maps allows team members to see a holistic view of construction data in a single map view, providing easier access to information.

Provide real-time visibility into construction progress, helping identify areas needing attention and optimizing workflows to reduce delays

Empower stakeholders to track milestones and progress visually by mapping project data geographically

Optimize resource allocation and management by consolidating all project data into one unified view for more efficient decision-making

Enhance collaboration and communication by giving all stakeholders access to real-time project updates through a shared visual platform

Manage photos and their placement on the map using the web or mobile app

See available photos on the web and mobile app displayed as thumbnails on a map, and select to open to full-size

Select and manage photos by date range, enabling or disabling them in Maps on a project-by-project basis

Use Photos in the mobile app to update a picture’s coordinates

Stop jumping between apps to get a clear view of your project’s status.